Salt-Resistant Sealers & Finishes for Coastal Patios in Hollywood

Concrete Patio Hollywood

Having a house in or near the area of the Hollywood coastline has its benefits when it comes to the view from your home; however, the coastal area can be unforgiving to outdoor structures. The saltwater spray off the ocean, the extreme sun and heat, combined with high levels of humidity, are all a threat to unprotected building materials, particularly those that will be exposed (such as a concrete patio). The unprotected surface of a concrete patio can rapidly deteriorate through cracking and spalling, discoloration, and weakening of the structural integrity of the patio. Protecting your concrete patio is not something you have to do; protecting your concrete patio is something you HAVE to do if you want to maintain both your enjoyment of your patio and the monetary value of your property.

Coastal Concrete Patio Deterioration – The Science Behind It

Coastal areas have a much faster pace of deteriorating concrete than other locations because of the chloride ions in airborne salt spray depositing micro-clusters of chloride particles directly onto the concrete surface. As time progresses, the chloride ions absorb into the porous nature of the concrete and finally make contact with the interior steel rebar. Once the chloride ions come in contact with the rebar, they initiate a rapid electrochemical reaction, and the steel begins to rust aggressively. Once the rebar rusts aggressively, the rust grows and exerts massive pressure on the concrete surrounding the rebar, resulting in cracks and spalls, which a common indicators requiring concrete foundation repair.

In addition to the aggressive chemical reactions initiated by the chloride ions, the intense UV radiation and high temperatures experienced throughout the year in Hollywood contribute to thermal expansions and contractions. Both of these factors individually weaken the top surface layer of the concrete. The combination of the chemical and thermal stresses necessitates a multifaceted defense strategy that is specifically designed for the local climate. Protecting your investment in your outdoor living space requires taking a proactive approach.

Selecting the Correct Sealer

When it comes to protecting your concrete patio from the effects of the coastal climate, selecting the correct sealer is the most important decision you will make. There are two forms of sealers that are suitable for protecting your patio from the coastal environment: topical and penetrating. Both have their own set of benefits and drawbacks; therefore, the type of sealer you select depends on the desired aesthetic and degree of protection you are seeking.

Topical Sealers create a barrier of protection on the surface of the concrete, typically producing a “wet look” or high-gloss finish. Topical sealers are very effective at repelling water and chloride ions. However, they are subject to peeling due to improper application and need to be reapplied every two to three years. Penetrating Sealers, such as silane or siloxane, react chemically with the concrete to produce a hydrophobic barrier under the surface. Unlike topical sealers, penetrating sealers do not change the appearance of the concrete and offer superior long-term protection against the absorption of salt. Typically, a high-quality penetrating sealer is the best option for the majority of Hollywood applications.

Marine Grade Finishes

Beyond sealing, special finishes offer additional protection for the look and durability of a concrete patio. Marine-grade finishes are designed to withstand prolonged exposure to severe environmental conditions such as standing water and salt. Many marine-grade finishes utilize high-performance polymers such as specialized urethanes or epoxy coatings to provide a sacrificial layer against wear and tear.

Specialized marine-grade finishes may also offer decorative concrete options in Hollywood, such as custom colors or exposed aggregate. When properly applied, marine-grade finishes create an impervious layer that completely blocks the entry of salt and moisture into the concrete. An additional benefit of using marine-grade finishes is the inclusion of non-slip additives in the final coat of topical sealers. Non-slip additives create a textured surface that offers traction when wet and prevents slipping hazards. Since safety and durability must be considered together, the use of non-slip additives is a must when applying topical finishes near a pool or high-traffic areas.

Surface Preparation is Not Optional

The performance of any sealer or finish depends solely on the surface preparation of the concrete patio. Surface preparation refers to the thorough cleaning of the concrete to remove all dirt, oils, efflorescence, and previous sealers. Simply power-washing the surface is not sufficient for complete surface preparation. Surface preparation includes the creation of a surface profile using chemical etching or mechanical abrasion (grinding) to allow for deep bonding of the sealer. If an older degraded sealer is left on the surface of the concrete, the new coating will simply peel off. Properly preparing the surface of the concrete eliminates any residual salt and neutralizes the surface, allowing for the successful application of a penetrating sealer. Therefore, surface preparation is not optional.

Application Techniques & Environmental Controls

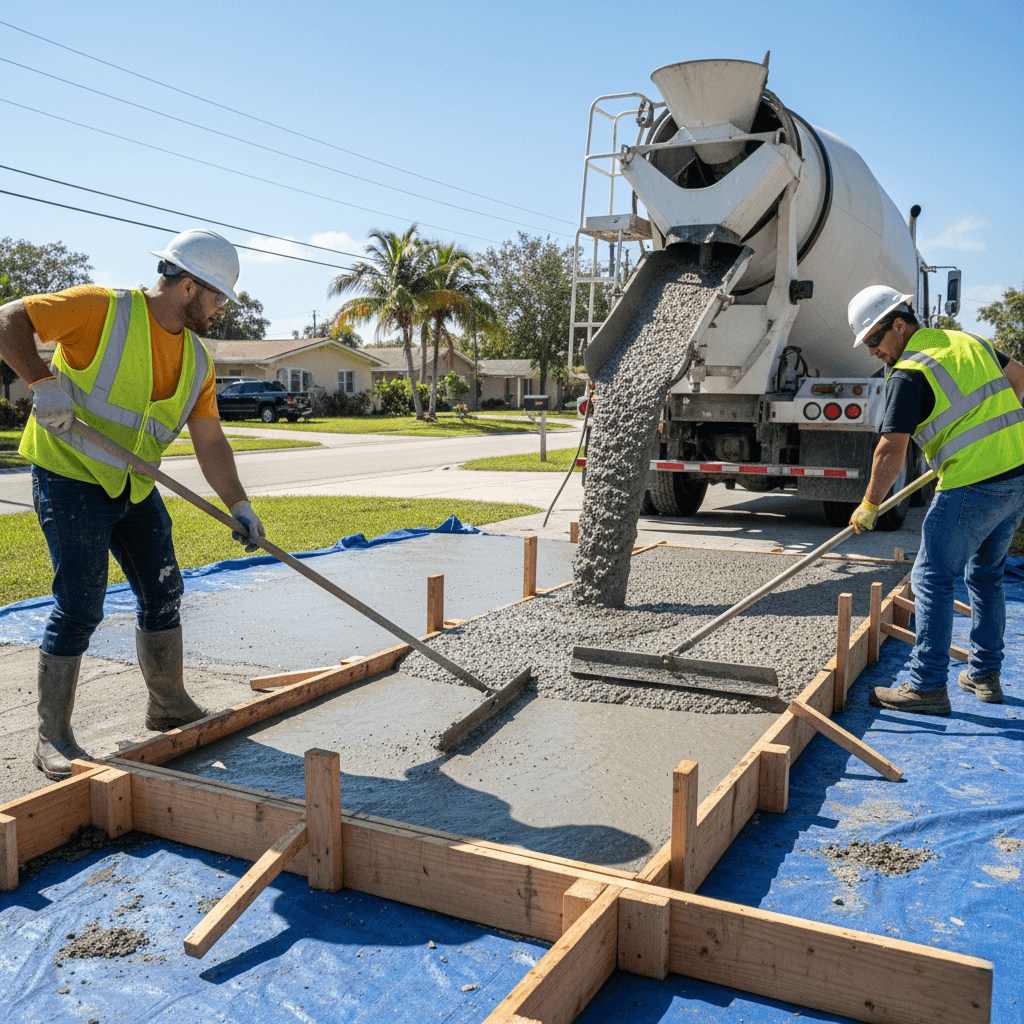

The extreme weather conditions in Hollywood dictate the application techniques and schedules. The application of sealers or finishes in direct sunlight causes the product to dry too quickly, resulting in air pockets or poor adhesion. Similarly, excessive humidity can affect the curing process of many products. We apply the products at the optimal time, typically in the early morning or late afternoon, when the temperature is moderate te and there is less chance of excessive drying or curing problems.

The products must be applied evenly and uniformly, typically by means of low-pressure sprayers or rollers, to assure full coverage without creating thick, uneven puddles. In general, multiple thin coats of product will perform better than one thick coat of product, assuring a strong, layered defense. Additionally, the proper amount of cure time must be allowed between coats and prior to subjecting the surface to pedestrian traffic. Rushing the process will compromise the long-term effectiveness of the coastal concrete sealers.

Maintenance for Coastal Patios

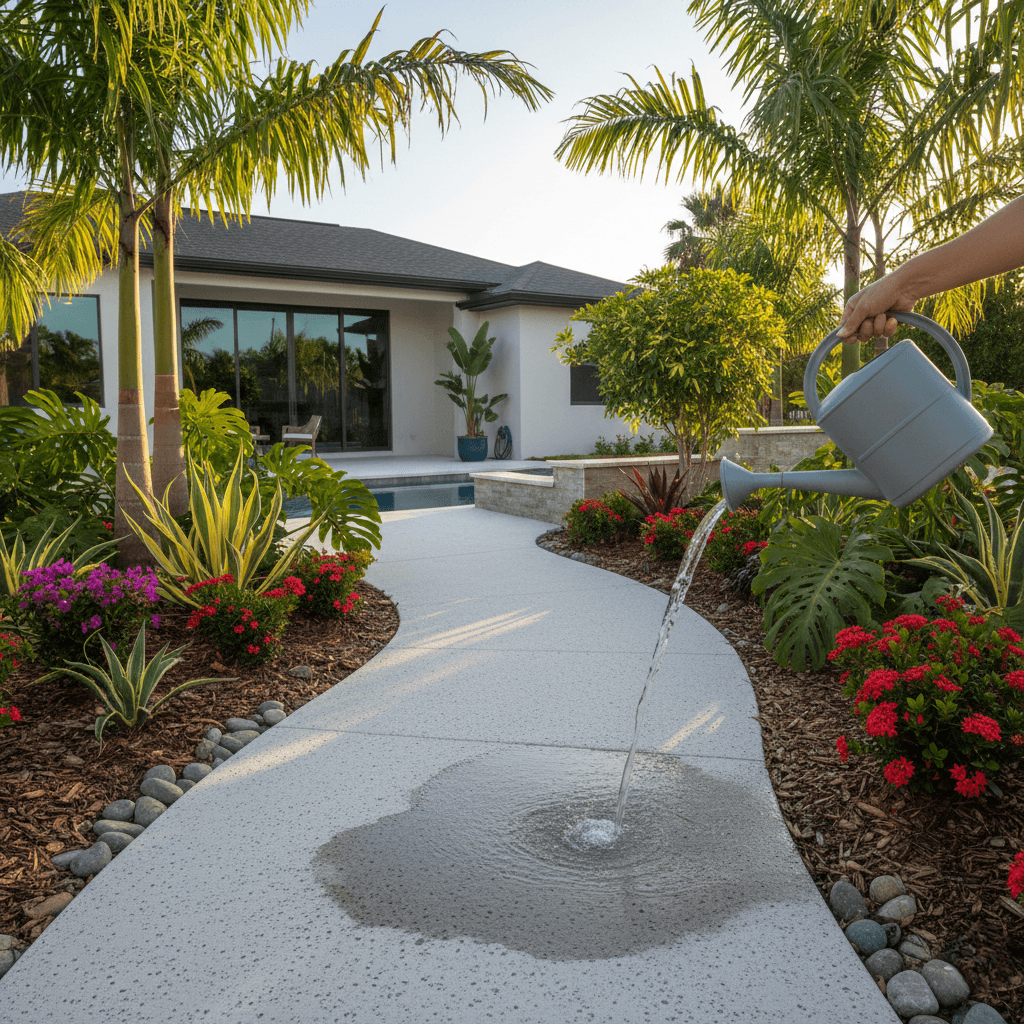

While even the best salt-resistant sealers will require periodic maintenance to achieve maximum results, homeowners must maintain their concrete patio regularly to maximize the performance of the sealer. Owners must clean their concrete patio regularly using a mild, non-acidic cleaner and a soft-bristle brush. Using acid-based cleaners to clean the concrete patio will either damage or strip away the protective surface layer. Quickly addressing spills or stains, particularly those containing chemicals or oils, will help maintain the integrity of the surface.

Additionally, owners must reapply topical sealers every two to three years, depending upon the amount of foot traffic and sun exposure. While penetrating sealers generally provide longer-term protection, owners should test their penetrating sealer every five to seven years to determine whether the product is functioning as intended. A simple water beading test will indicate whether the penetrating sealer is still providing adequate protection. Regular proactive maintenance is the key to maintaining the beauty and longevity of your coastal patio sealing.

Safety First – Non-Slip Finish Options

While durability is important for any concrete patio, safety is even more important, particularly around swimming pools or outdoor kitchens. Most standard sealers will create a slippery surface when wet. Fortunately, non-slip additives are available and can be incorporated into the final coat of topical sealers. Non-slip additives add fine polymer beads or sand-like particles to the finish, which adds texture to the finish without significantly altering the overall appearance. Non-slip finishes are a major priority in regards to safety for all decorative or heavily polished finishes.

An alternative way to achieve a non-slip finish is to create a textured finish on the concrete itself prior to applying the sealer. This can be done by brushing or lightly abrading the surface. Regardless of the method used to achieve a non-slip finish, we prioritize safety by ensuring that high-traffic and pool areas meet the required friction coefficient standards. A beautiful concrete patio should always be a safe and secure environment for family and friends; therefore, non-slip finishes are a necessity for the Hollywood lifestyle.

Protect Your Investment

Using generic sealing products will not provide the necessary protection against the extreme coastal conditions found in Hollywood. Our company specializes in advanced salt and UV-resistant concrete finishes that will guarantee the long life of your concrete patio. At King Concrete Hollywood, we use only marine-grade products applied with precise surface preparation to ensure your outdoor space is protected from the elements. Contact us today to find out how our sealing expertise can protect your investment in your concrete patio.