Waterproofing & Reinforcing Coastal Slabs in Hollywood, FL

Concrete Slab Hollywood

Creating foundations in Hollywood, FL, calls for much more than simply laying down a foundation layer. It requires using methods that are specifically designed to help prevent water from entering and also to provide support (reinforcement). The elevated water table, very low-density soils (sandy), and corrosive salt-laden air all contribute to an extremely challenging environment for a concrete slab. Both moisture entry into the structure and steel corrosion are the most common causes of rapid structural collapse, as long as they are neglected. Therefore, employing the latest methods in the field of methods to reduce/eliminate moisture and also to place the steel used in the slab to ensure the durability of any residential or commercial foundation is critical. We need to design the slab to survive the harsh tropical climate in which we build.

The Dual Enemy of Coastal Concrete Slabs

Concrete slabs near the coast battle two enemies: water and salt. Water vapor rises toward the slab through capillary action due to the high water table, causing mold, mildew, and flooring failure inside the structure. Without direct flooding, the constant moisture is destructive. Secondly, airborne chloride ions from the ocean penetrate the concrete’s pores and eventually reach the steel reinforcement, which is the primary source of rebar corrosion.

When rebar corrodes, it expands up to six times its original size, creating internal pressure that cracks the concrete. This is referred to as spalling and ultimately compromises the entire concrete slab. Therefore, to protect the slab from premature failure, a dual approach must be taken: create a moisture barrier and use corrosion-resistant reinforcement.

High-Quality Vapor Barrier Installation Is Mandatory For Moisture Mitigation Strategies

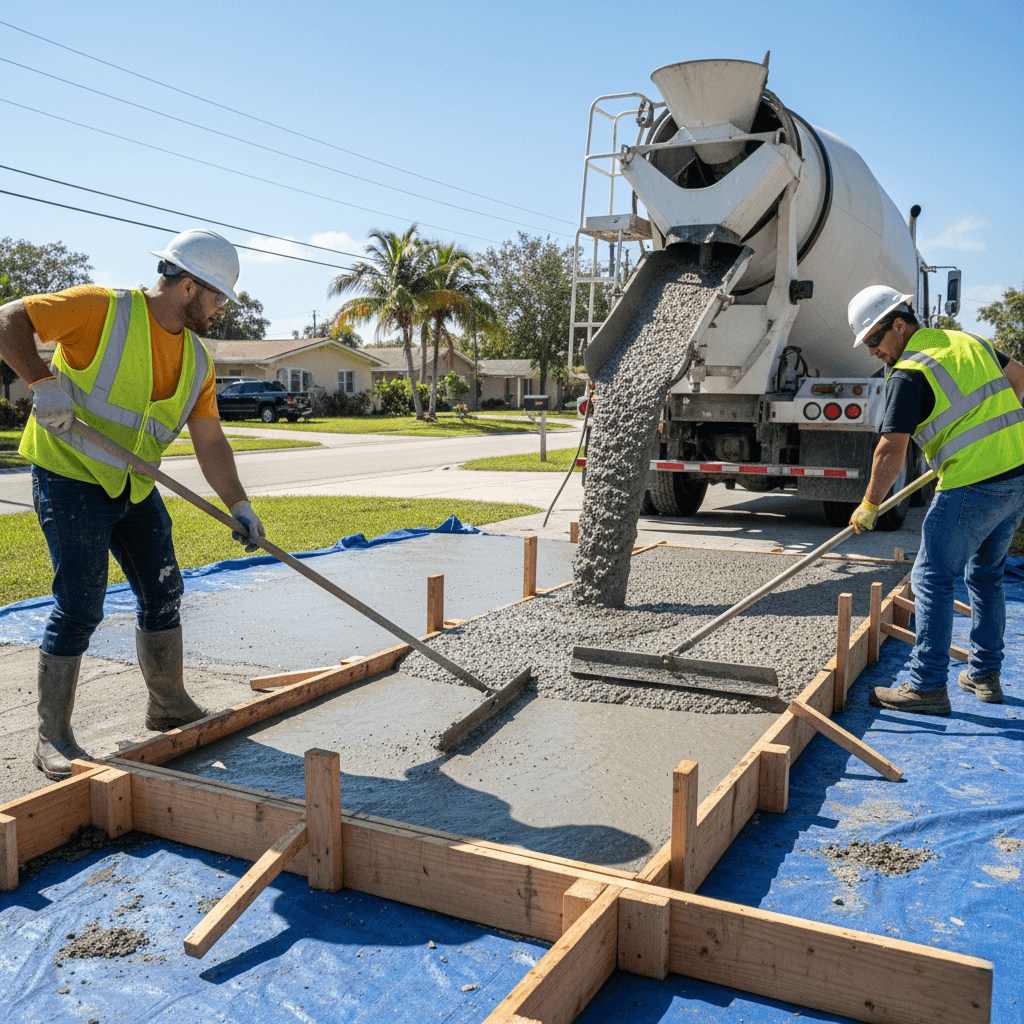

Installing a high-quality vapor barrier is mandatory for moisture mitigation strategies for any concrete slab in Hollywood. This barrier is a thick, durable sheet of polyethylene (poly film) that is laid directly over the prepared aggregate base prior to pouring the concrete. The objective of the vapor barrier is to physically impede the upward movement of water vapor from the ground into the slab. By doing so, it prevents moisture-related issues inside the structure.

We suggest using a minimum 10-mil-thick vapor barrier and ensuring that all seams are overlapped by several inches and taped with specialized tape. This creates a continuous and airtight barrier to ground moisture. Providing a good foundation begins with sub-slab moisture protection and protecting finished flooring, reducing humidity, and preserving the interior environment.

Choosing the Right Steel Reinforcement

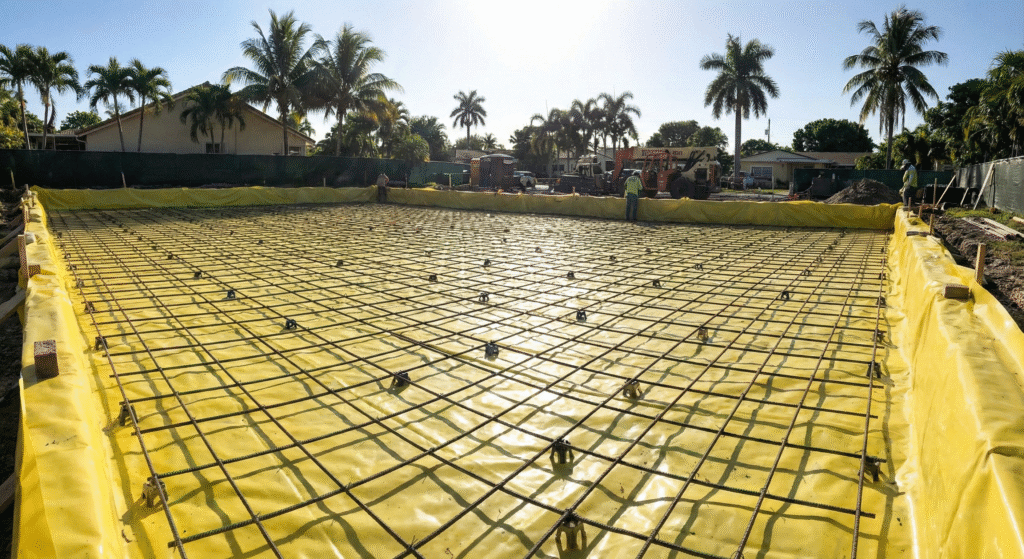

Steel reinforcement is essential to providing the tensile strength needed to support a concrete slab under shifting soil and heavy loads. However, standard carbon steel rebar is commonly used, and its vulnerability to chloride attack near the coast requires the use of alternative, more resistant materials for coastal residential slab pouring.

We often choose epoxy-coated rebar; this type of rebar has a protective plastic coating that slows down the corrosion process. Galvanized rebar is preferable to bare steel. The best option, although expensive, is to use fiberglass reinforcement, which is rust-proof. Regardless of the material chosen, the reinforcement needs to be placed properly – usually in the upper third of the slab – to resist tension forces effectively. Maintaining the steel’s elevation, using proper wire chairs during the monolithic slab construction process, is also important.

Admixtures That Provide Additional Waterproofing Protection

In addition to external barriers, the concrete itself can be designed to provide additional waterproofing protection. Adding crystalline waterproofing admixtures to the concrete mixture adds another layer of protection. These chemicals react with the concrete components to form non-soluble crystals within the capillary pores and effectively fill the concrete from the inside, making the finished concrete slab less porous to both water and corrosive chlorides.

Reducing the water-to-cement ratio of the concrete is also a basic method to provide waterproofing protection. A lower water-to-cement ratio will produce a denser, stronger, more impermeable concrete with fewer natural voids for moisture to enter. By combining these specialized admixtures with a dense, properly mixed concrete, a strong internal defense against the humid, tropical environment is created, providing superior layered coastal slab waterproofing membrane protection.

Protection Of Concrete Cover And Edges

The thickness of the concrete above the steel reinforcement – referred to as concrete cover – is a significant factor in the prevention of corrosion. Due to the increased risk of chloride penetration, the cover should be larger when working near the coast. When installing a concrete slab, industry standards may require a specific amount of cover; however, experienced professionals in Hollywood often add a small amount of additional cover to increase the durability of the slab. The absence of sufficient cover enables salt to reach the rebar much faster.

Additionally, the edges of a concrete slab where the steel is closer to the surface need special consideration. The application of a liquid waterproofing compound or a specialized cement-based coating to the exposed edges of the slab provides an added seal. These protective measures assure that the vulnerable perimeter areas, which are constantly exposed to splash and salt-laden air, do not fail prematurely. Protecting the edges of the slab greatly increases its lifespan.

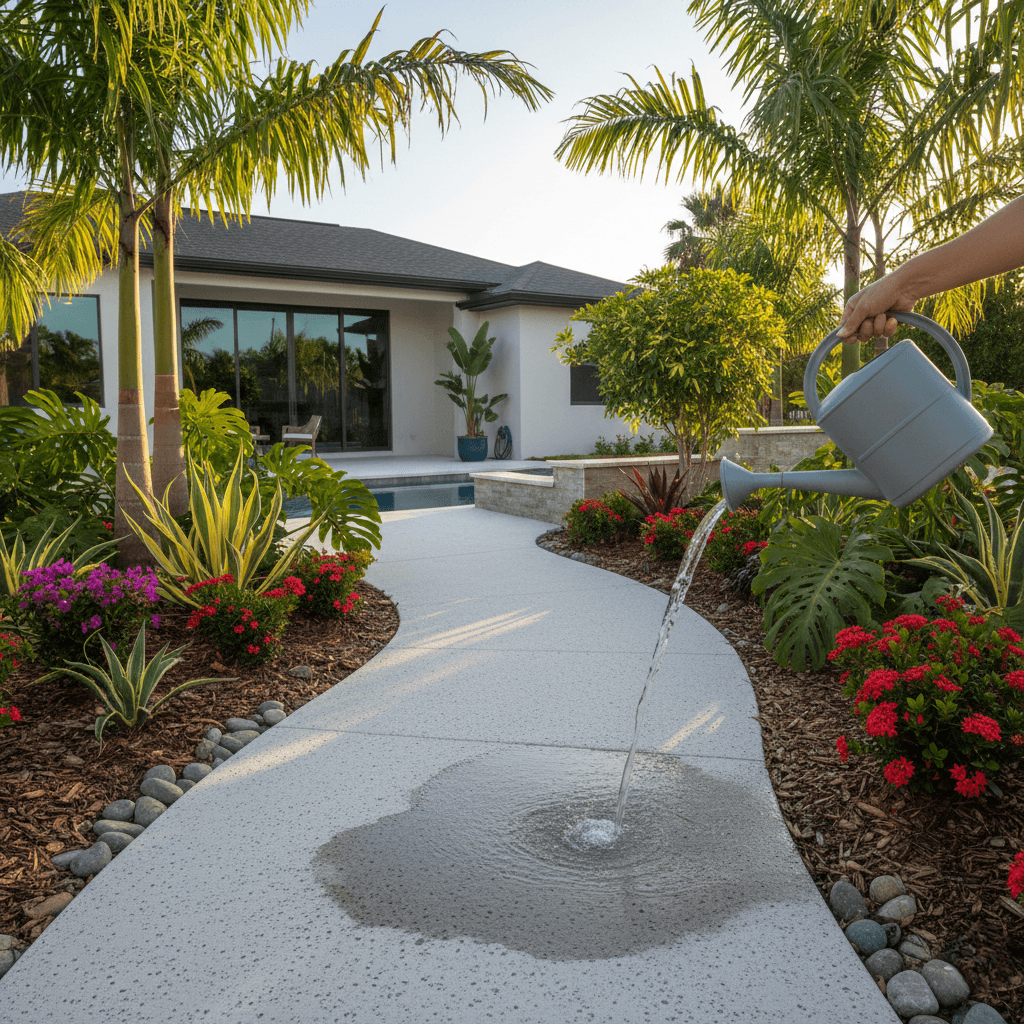

Maximizing Strength and Density Through Proper Curing

While the final step in constructing a waterproof and durable concrete slab is to apply a good coat of sealer, the most overlooked step is curing the concrete. Curing is the process of maintaining a certain level of moisture and temperature over time to allow the concrete to achieve its full potential in terms of strength and density. Due to the extremely hot, dry, and windy climate found in South Florida, the concrete dries rapidly, leading to cracking on the surface and loss of strength.

We use curing compounds, wet curing techniques (such as continuous sprinkling), and curing blankets to cure the concrete immediately after the finishing process is completed. As previously stated, slow and controlled curing directly relates to reduced permeability and increased compressive strength. A dense, well-cured slab will naturally resist moisture and chemical intrusion more than a poorly cured slab that dried too quickly.

Coastal Slab Waterproofing Requires Specialized Expertise

Constructing a concrete slab near the Hollywood coast requires specialized experience beyond what general builders offer. The combination of high water tables, sandy soil, and salt corrosion necessitates a foundation constructed with specialized materials and procedures. We possess the knowledge and skills of coastal slab waterproofing membrane installation, advanced reinforcement, and local building codes. At King Concrete Hollywood, we are dedicated to developing foundations that are engineered to last and provide maximum moisture and structural protection for your home. Call us today to invest in a foundation developed specifically for the coast.