Hollywood, FL Concrete Driveways: Best Practices for Sandy Soil

Concrete Driveway Hollywood

A successful concrete driveway in Hollywood, Florida, is not possible without knowledge of the area’s environment, which is an environment that is subtropically located. Our driveway will be built on a surface made of sand (unlike areas around the country where you can build on solidly packed soils), thus the geotechnical requirements of the area pose a challenge to properly install a driveway with no cracking or settlement. To ensure that your investment will hold up to Florida’s weather conditions, you will require some experience in how to install a driveway in the local geology. The generic method of construction will simply not work in building a concrete driveway in Hollywood, Florida.

Why is Hollywood’s Sandy Soil Important to Concrete?

All Hollywood properties have a sandy/limestone fragment sub-base. This greatly affects the bearing capacity of the ground and its ability to absorb water. Sandy soil is unstable under loads such as traffic and heavy weights. When an unprepared sand base is subjected to a heavy weight, such as a car driving over it, the sand will shift, settle unevenly, and develop cracks. Thus, recognizing this is the first step to success in the installation of a driveway. All projects located within the area of Hollywood must take into consideration the inherent movement of the sub-grade.

Water management is another major concern with this type of soil. Sand allows water to drain quickly; however, heavy rainfall, fluctuations in the water table, etc., can wash away the underlying particles in the soil. Erosion of the underlying soil particles creates voids under the slab, ultimately leading to structural failures. Therefore, long-term durability is dependent upon the base preparation and compaction used for the project. To obtain a stable and reliable outcome, we must combat the soil’s inherent characteristics.

Step 1: Preparing the Base for a Driveway Installation

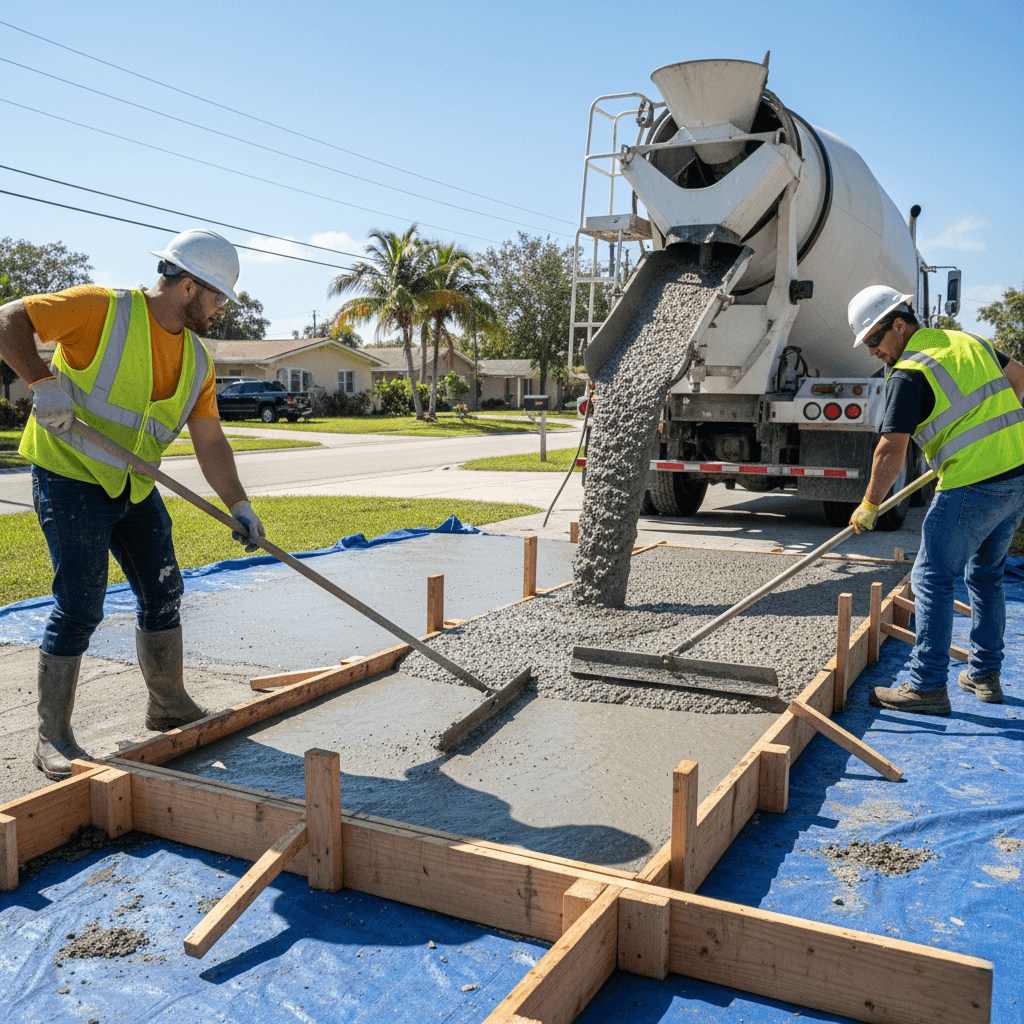

Preparing the base is the most critical step in a successful concrete driveway installation. Normal procedures include excavation of the area to a predetermined depth, removal of all organic matter that could potentially break down in the future, and the installation of a base layer. The base layer is typically made of crushed-rock/limerock aggregate. The purpose of the base layer is to act as a structural cushion. The base layer must be compacted to its maximum density. If the base layer is not properly compacted, it is the number one reason why concrete driveways fail in sandy areas.

We use a variety of different types of compaction equipment, including vibratory plate compactors, to achieve a minimum of 95% modified proctor density. Achieving a minimum of 95% modified proctor density ensures that the base layer will not settle further after the weight of the concrete is applied. A geotextile fabric can also be installed between the native sand and the aggregate layer to prevent the two layers from intermixing. Preventing the two layers from intermixing maintains the integrity of the crushed-stone base layer and provides long-term load-bearing capacity. As previously stated, investing time and money in the first phase of the process will save exponentially more money in the future on repairs to residential foundations.

Reinforcement Methods for Coastal Stability

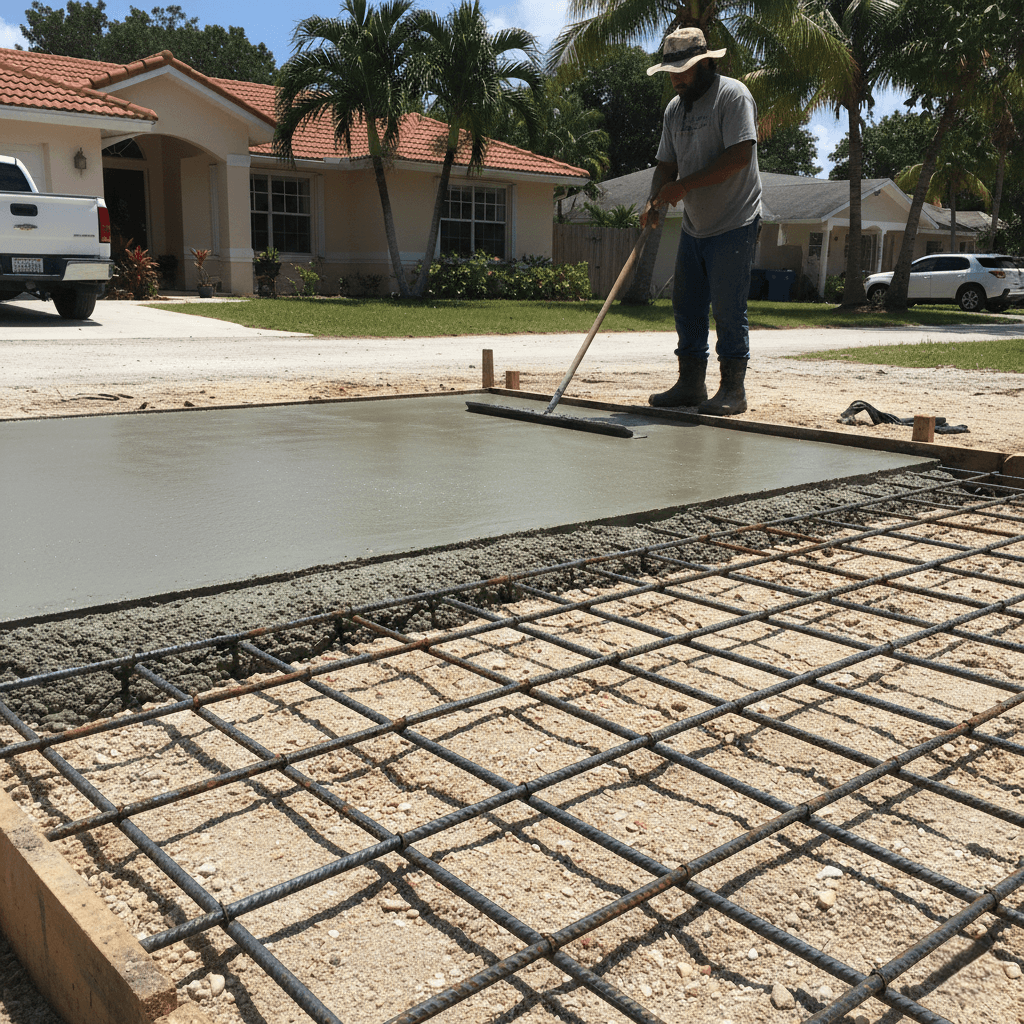

Once the base layer has been completed, the next task is to provide internal reinforcement to the concrete slab. Concrete has high compressive strength, but low tensile strength. In other words, concrete resists compression well but fractures easily when subjected to tension or bending. As previously stated, the sandy soils of Hollywood will continue to shift and bend the slab. Therefore, the internal reinforcement of the concrete slab is very important when constructing a high-quality concrete driveway.

As a general rule of thumb, it is suggested to use steel reinforcement (either welded wire mesh or steel rebar) throughout the concrete slab. Steel rebar should be installed in the center to the upper third of the concrete slab and should be tied together in a grid pattern. The rebar should be held off the sub-base with concrete blocks or wire chairs. In doing so, the rebar will help to resist the tensile stresses that are induced when the sand continues to shift. Without proper internal reinforcement, even the best-prepared base layers will eventually give way to the forces of nature and traffic.

Moisture Control Using Vapor Barriers

Due to the high water table and high humidity levels in Hollywood, the use of a vapor barrier/moisture barrier is highly recommended prior to pouring the concrete driveway. Even though the driveway is outside, there is always a constant upward force of moisture (known as capillary action) that can negatively impact the concrete mix and result in problems such as efflorescence. Installing a durable plastic sheet (vapor barrier/moisture barrier) will block moisture from rising from the sandy soil to the newly poured concrete.

A suitable vapor barrier/moisture barrier would be a heavy-duty plastic sheet (polyethylene) that must be installed with great care to avoid overlapping and penetrating the barrier. Care must be taken to ensure that the barrier is properly sealed in areas adjacent to garages and/or near the main foundation of the house. With the barrier in place, the integrity and quality of the concrete will be protected both internally and externally, and the concrete will cure properly to reach its maximum desired strength.

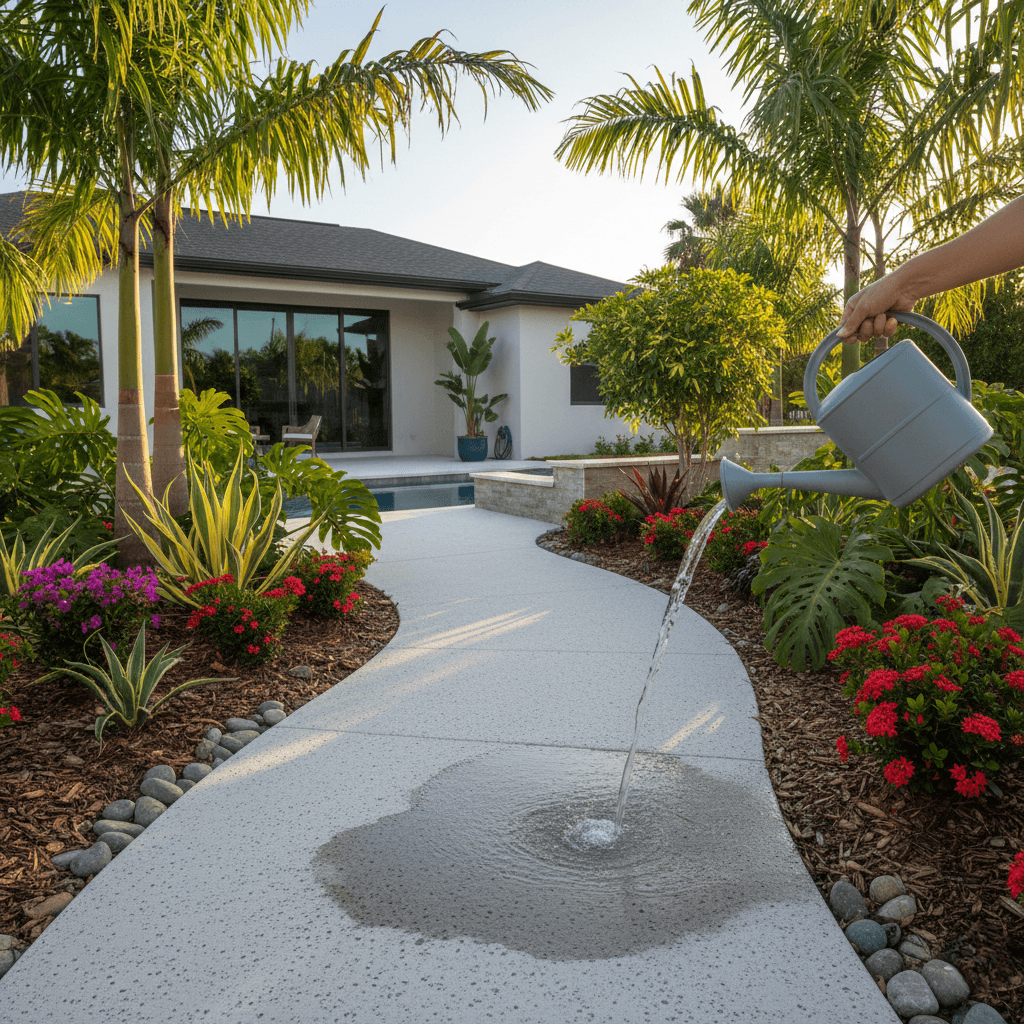

Drainage and Slope Requirements

Poor drainage is a continuous threat to any concrete surface in a flood-prone area, such as Hollywood. Standing water along the edges of the driveway can compromise the prepared base layer. Therefore, the concrete driveway must be constructed with a deliberate, gradual slope to direct water away from the house and towards the street or a storm drain. Typically, a minimum slope of 1/8 to 1/4 inch per foot is needed. Where feasible, installing small catch-basins or channels can efficiently handle large amounts of runoff. Proper drainage prevents erosion and minimizes the potential for hydrostatic pressures to build up beneath the slab. Local experts are familiar with the local stormwater regulations and elevation requirements, ensuring you of full compliance and performance during Florida’s intense rain events. Proper drainage is key to extending the life of your concrete driveway.

Placing Control Joints

Even if the base layer is perfectly prepared and reinforced, concrete will still crack. This is due to normal thermal expansion and contraction and drying shrinkage of the concrete. The objective is not to eliminate cracking, but to control the location of the cracks. This can be achieved through the placement of control joints.

Control joints are shallow grooves (cuts) that are placed in the concrete surface to allow the stresses to crack the concrete below the joint instead of randomly across the surface. These joints should be spaced approximately three times the thickness of the slab apart. Additionally, these joints should be placed in areas where the driveway changes direction or where there are fixed objects (such as manholes). Placing control joints in the concrete slab is a best practice for every poured concrete project.

Mix Design

The quality of the mix design significantly impacts the overall durability of a concrete driveway, particularly in coastal environments. A high-quality mix for a Hollywood area should contain a low water-to-cement ratio, resulting in less porous concrete. Less porous concrete resists water penetration and helps to reduce rebar corrosion caused by salt-laden air. We frequently add chemical admixtures to our mix designs to enhance their resistance to coastal conditions. Chemical admixtures include water reducers and corrosion inhibitors. The quality of the mix design is the backbone of a long-lasting concrete driveway.

Achieving the correct slump, a measure of the mix’s consistency, is essential. The mix must be workable, yet not overly wet, so that segregation of the aggregate does not occur. On-site monitoring of the slump will ensure optimal strength and finishability of the concrete. Our dedication to materials science will ensure that the finished product will function as designed for many years to come.

Partner with Us for Success

If you want to install a concrete driveway in Hollywood that will last for many years, you need local knowledge and these unique engineering practices. Every aspect of the project counts, from stabilization to reinforcement and drainage. We have the experience to guide you through the local challenges. At King Concrete Hollywood, we guarantee that your concrete driveway will meet the highest performance and durability standards and protect your property value for years to come. Contact us today.