When Concrete Resurfacing Beats Replacement in Hollywood, FL

Concrete Resurfacing Hollywood

When there are signs of wear on Hollywood area homeowners’ driveways, patios, and walkways, they have a big decision to make. They can either replace the old concrete completely or resurface it. Replacement will give them a fresh slate, while concrete resurfacing is less costly and less intrusive as long as the structural integrity of the slab is intact. In addition to saving time and landscaping disruptions, choosing the correct method will save homeowners money. A professional assessment will help identify the best course of action for the homeowner’s specific concrete repair.

Evaluating Your Concrete’s Structural Integrity

There are significant differences between resurfacing and replacing a concrete slab. Resurfacing is appropriate only when the original slab is structurally sound. First, we perform a detailed examination to locate extreme cracking, heaving, or large-scale settlement of the slab. Hairline cracking, staining, or minor surface spalling on the surface are suitable for a resurfacing solution. These are surface-level or cosmetic damage.

However, when large cracks are extending through the thickness of the slab, large areas of unevenness caused by a failed subbase, or large amounts of concrete lifted out of the ground by tree roots, replacement is generally the better long-term solution. Structural problems imply that the damage is under the concrete, and you must replace the subbase. Our evaluation is to identify the root cause of the damage so we do not merely hide a larger problem.

Advantages of Resurfacing

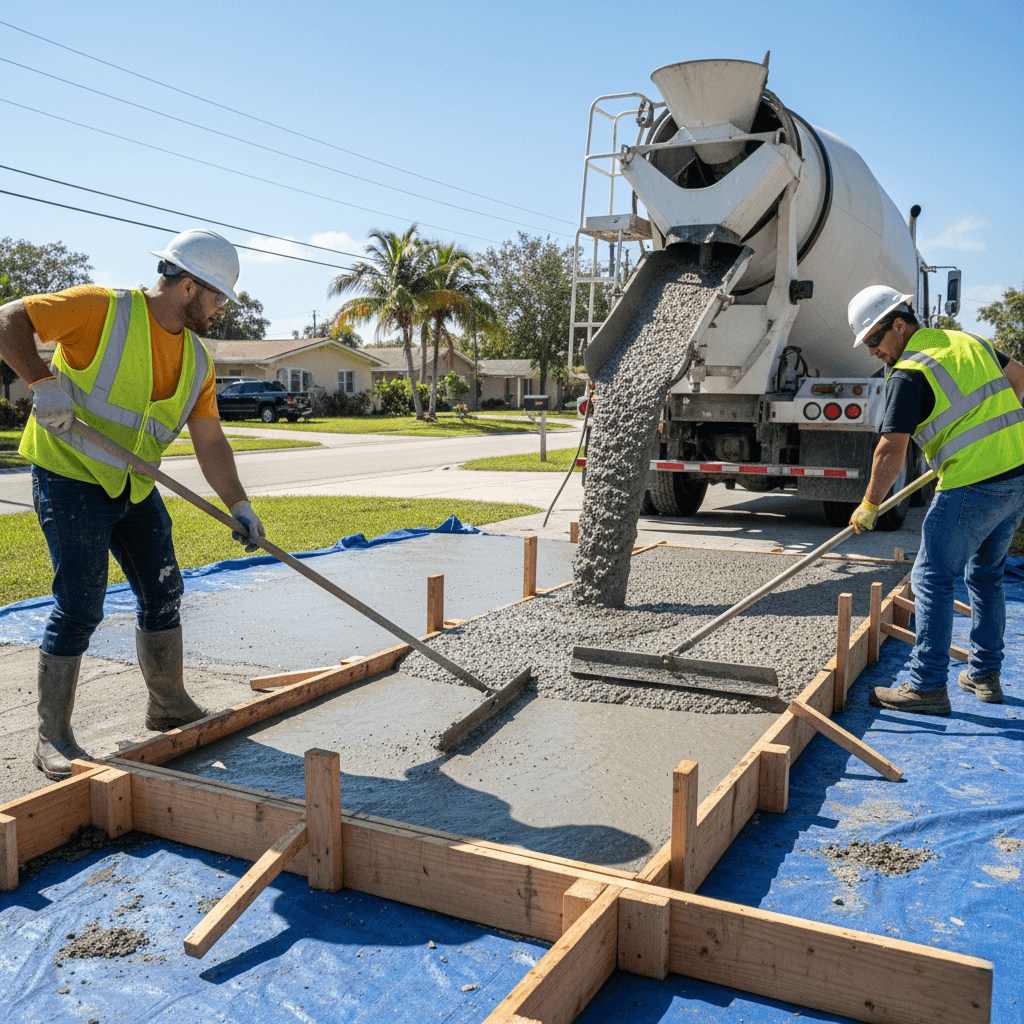

Concrete resurfacing is an application of a thin (typically one-fourth inch), polymer-modified cementitious coating (often called an overlay) to the prepared surface of the existing concrete. There are many advantages of resurfacing for Hollywood residences. The biggest advantage is the cost savings. Resurfacing saves the homeowner money by eliminating the costs associated with demolition, removal of debris, and the cost of new concrete. For residents seeking to improve their residence aesthetically, this is a big benefit.

Another advantage is that resurfacing does not disrupt the resident nearly as much as replacement. The equipment used in replacement processes includes heavy machinery, generators, pumps, etc. As well, the process of replacement involves digging into the surrounding yard, which causes damage to the landscaping. The resurfacing process is a cleaner, faster process that results in significantly less disturbance to the resident. Additionally, resurfacing provides a clean slate, allowing you to enhance your design with new colors, textures, or stamp patterns and immediately increase curb appeal.

Resurfacing for Aesthetics

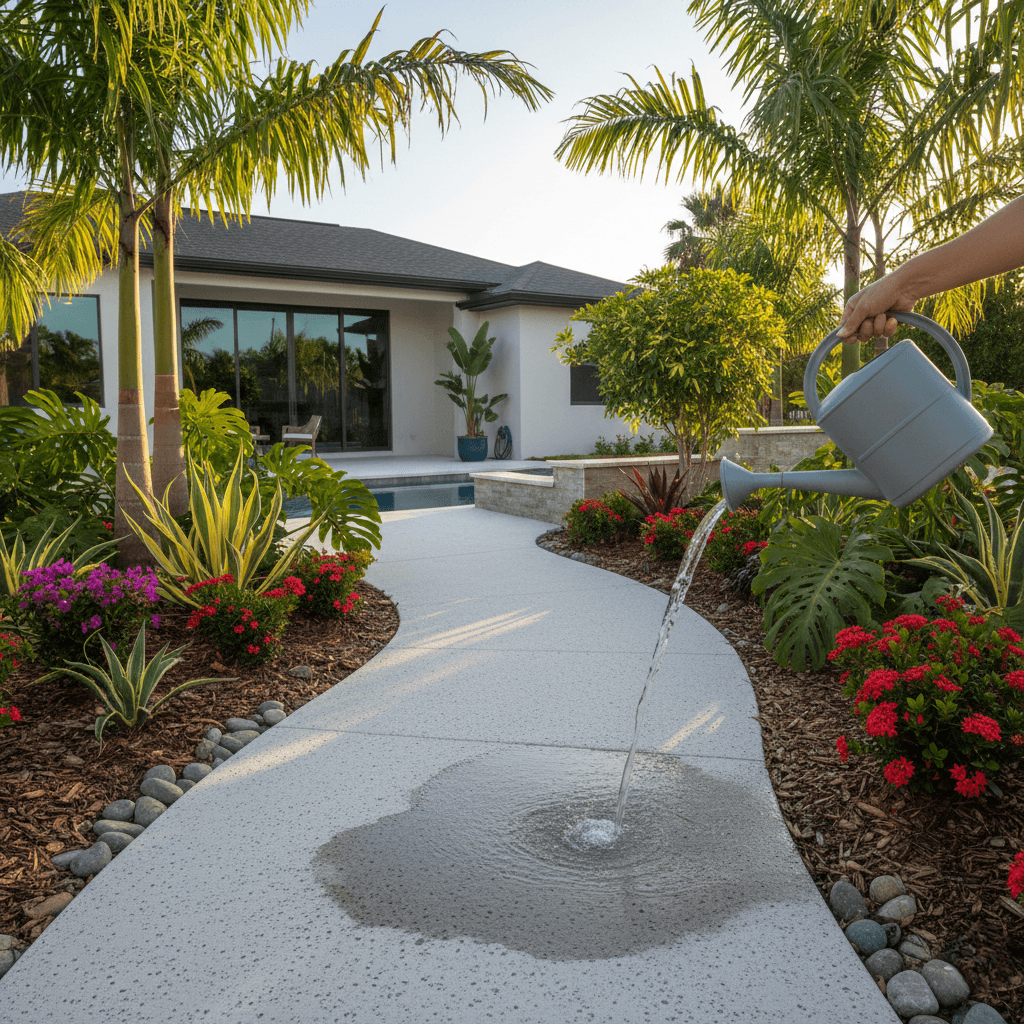

The aesthetic enhancements provided by resurfacing are numerous, making it a very popular choice for Hollywood pool deck and patio owners. The modern polymer overlays available provide far greater design flexibility than a standard broom finish. Pool deck owners and patio owners now have access to specialty epoxy overlays or polymer cement coatings that allow them to create a luxurious look without the price of a high-end material such as tile, granite, or slate. This is especially important for residents who wish to obtain a luxury look without the expense.

Additionally, homeowners have virtually unlimited choices regarding the color scheme for their resurfacing project. They can select colors that reflect the exterior of their home, the tropical landscaping, or create a unique color combination. Traction additives can also be added to the final coat to provide a slip-resistant finish on pool areas or high-traffic walkways. Not only does resurfacing restore the surface, but it also redoes the area, providing a durable, low-maintenance decorative solution.

Preparation for Resurfacing

Proper surface preparation is critical to the success of a resurfacing project. To create a strong bond for the new overlay, the existing concrete must be free of dirt, grime, and other contaminants, porous, and solid. This is typically accomplished through power-washing and/or chemical cleaning to remove oil and grease, and mechanically grinding or shot-blasting the existing concrete. All prior coatings, sealers, etc., and any loose or flaking material must be thoroughly cleaned away. Failure to properly clean the surface will result in the overlay delaminating or peeling off quickly.

After the surface is clean, all of the existing cracks must be repaired. While structural cracks are the type of cracks that would necessitate replacement, non-structural cracks require special crack-filling techniques and, in some cases, the installation of crack-isolation membranes before the overlay is installed. If this is not done, the existing movement of the cracks will be transferred to the new surface, resulting in almost immediate failure. We spend a great deal of time preparing surfaces to ensure the strongest possible bond.

When to Replace vs. Resurface

Although concrete resurfacing is quite versatile, it cannot solve significant structural problems. If the concrete has sunken more than an inch or if multiple sections of the slab are severely fractured, then the entire base of the structure must be evaluated and corrected. Resurfacing simply places a thin layer on top of the existing slab and does nothing to correct issues related to the sub-base, such as soil erosion or root damage. In those cases, replacement, although more expensive, is the long-term answer.

Replacement permits the concrete contractor to begin again, correct any faulty drainage systems, and stabilize the underlying sandy soil. Replacement is the opportunity to install new, substantial reinforcement and correct any grade problems. If the slab has previously been resurfaced multiple times, the cumulative number of layers may make another resurfacing solution impractical. A professional consultation will provide a driveway surface restoration analysis to determine the best course of action.

Durability and Maintenance of the Overlay

If properly applied, a concrete resurfacing overlay can last for decades with proper maintenance. The polymer additives in the overlay make it extremely resistant to abrasion, impact, and Hollywood’s weather. Similar to new concrete, overlays must have a high-quality, UV-resistant sealer applied as the final coat to protect the color and prevent water absorption. The sealer should be reapplied every few years to keep the protective barrier intact.

Maintenance is easy; just use a mild detergent to clean. Never use harsh chemicals or scrape aggressively, as it can damage the decorative finish. With proper maintenance, you can extend the lifespan of the resurfacing solution and enjoy years of a beautiful appearance at a small percentage of the cost of replacement. By using quality materials and experienced application, you can achieve this durability.

Choose Experienced Local Contractors

Concrete resurfacing requires special skills and knowledge about the local climate’s effect on materials. We have the experience to inspect the condition of your existing slab, properly prepare the slab, and apply high-performance overlays that will withstand coastal conditions. We guarantee a completed product that looks excellent and is designed to be durable. At King Concrete Hollywood, we specialize in concrete resurfacing services for homeowners seeking a cost-effective alternative to full replacement while maintaining quality and aesthetics. Contact us today to review your repair needs.